We screen print, you heat press!

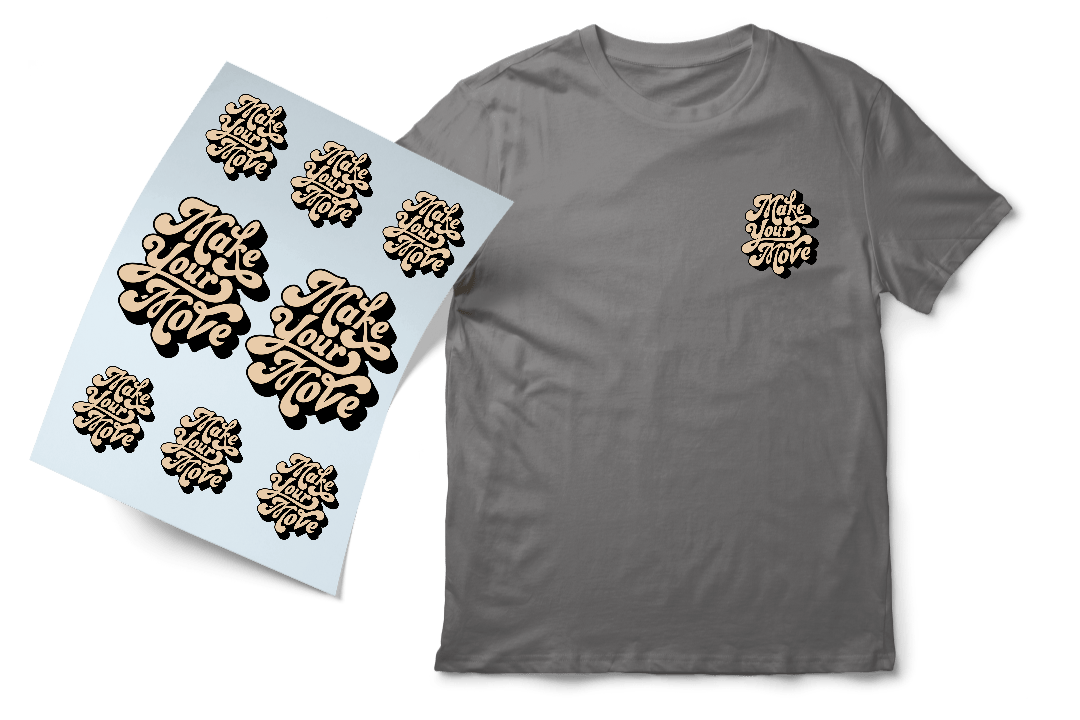

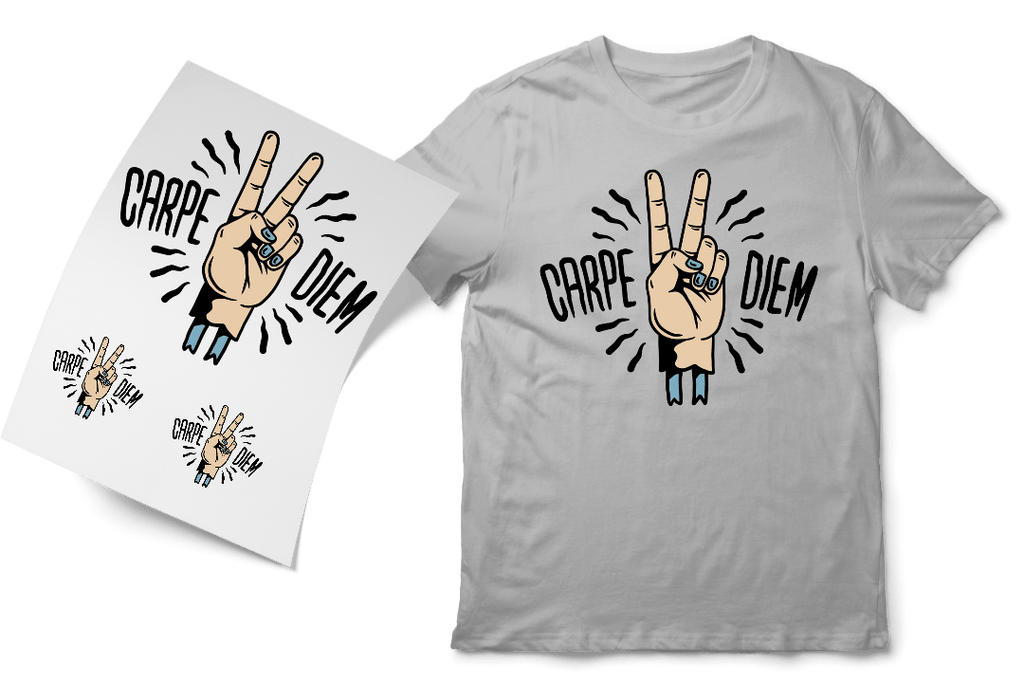

There is a lot you can do with heat transfers – choose the right one for your project

Screen Printed Transfers : Pantone colors, similar to screen printing finish on garment. Up to 6 printed spot colors on same sheet, soft and smooth hand feel.

- Most popular : Ultra Soft Transfer (t-shirts, hoodies, polos, sweatpants)

- Heat sensitive : Athletic Transfer (jackets, nylon bags)

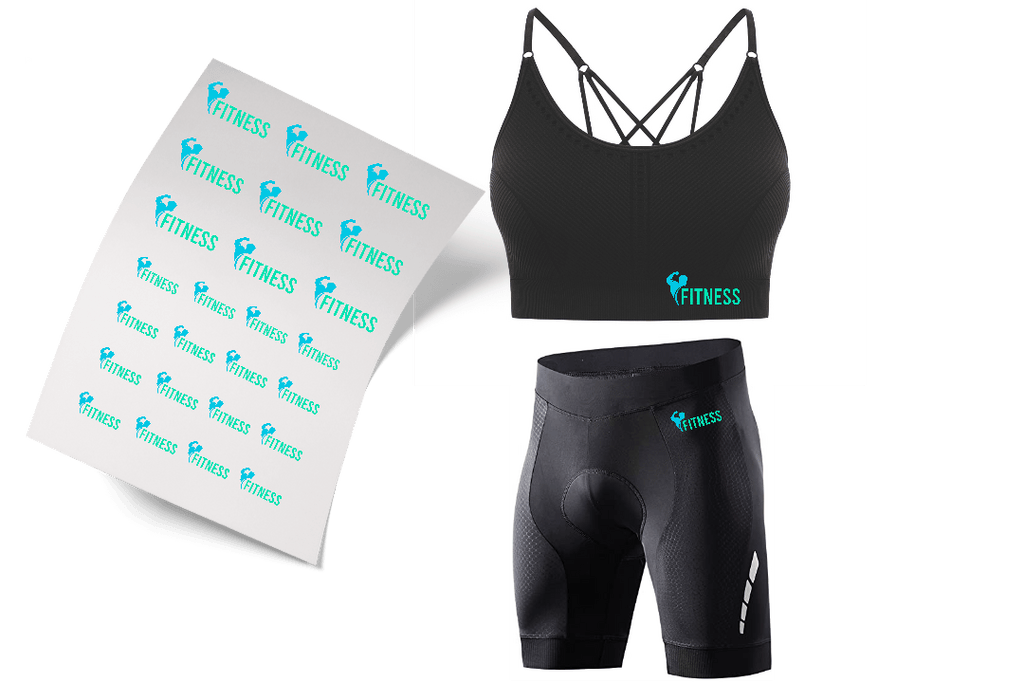

- Stretchable fabric : Performance Transfer (leggings, swimwear)

Ultra Soft

Features : Most popular transfer for general garments.

Fabrics : 100% Cotton, 100% Polyester, 50/50 Cotton/Polyester, Tri-Blends.

Transfer Type : Hot Peel Release

Printing method : screen printed

Opacity : Good opacity, for dark garments we recommend adding a white underbase.

Ultra Color

Features : Single color transfer option. Color is printed in two layers for maximum opacity.

Fabrics : 100% Cotton, 100% Polyester, 50/50 Cotton/Polyester, Tri-Blends.

Transfer Type : Hot Peel Release

Printing method : screen printed

Opacity : Great opacity

No Feel

Features : Similar to water based screen printing. Softest hand feel.

Fabrics : 100% Cotton

Transfer Type : Hot Peel Release

Printing method : screen printed

Opacity : Lower opacity on dark garments

Athletic

Features : For heat sensitive garments. Shiny print finish.

Fabrics : Lycra, Nylon, Elastane, 100% Cotton, 100% Polyester, 50/50 Cotton/Polyester

Transfer Type : Cold Peel Release

Printing method : screen printed

Opacity : Good opacity

Performance

Features : Super stretchable transfer

Fabrics : Lycra, Nylon, Spandex,

100% Polyester

Transfer Type : Cold/Hot Peel Release

Printing method : screen printed

Opacity : Good opacity

Glow in The Dark

Features : Any color available in glow in the dark option.

Fabrics : 100% Cotton, 50/50 Cotton/Polyester, 100% Polyester

Transfer Type : Hot Peel Release

Printing method : screen printed

Opacity : Good opacity

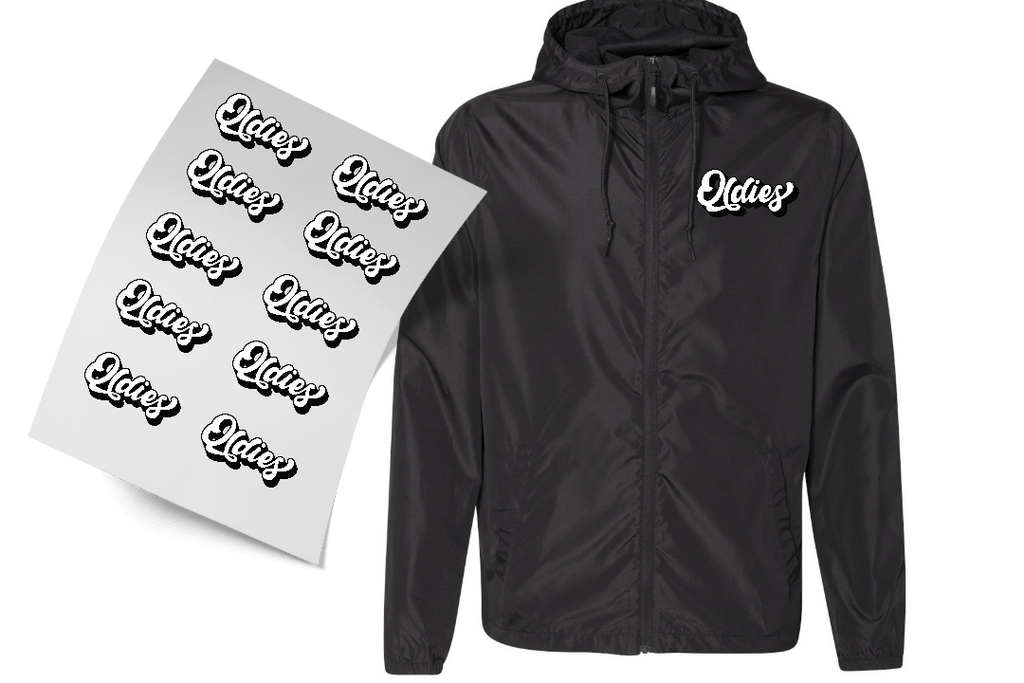

Why choose Screen Transfers over DTF?

Screen Printed Transfers : Printed using plastisol inks. Each color of the design is printed separately. Ink is printed through a screen and a mesh, like traditional screen printing process. The same screen is reused multiple times to print all of the sheets.

1 – Cost efficient transfer option for high volumes.

2 – Best option for single color or two color transfers. Low cost, starting at 1.20$ per sheet.

3 – More breathable feel on the shirt than DTF.

4 – Exact pantone color matching for your branding.

5 – Possible to make special printing (glow in dark, puff, performance, shimmer).

6 – White ink is higher in opacity.

7 – Great option for faster production due to hot peel release.